- ProductsElmo Rietschle CompressorsCompressor for transit applicationsAir distribution system & acc.Elmo Rietschle Compressors

Robuschi

Vacuum pumpsBreathing air systems

Pre-assembled packages

- Parts

- Services

- Industries and applications

- Equipment sales

- Gallery

Replacement parts for industrial air & gas equipment in Montreal (Kirkland), Quebec

Aircom Technologies of Montreal is an authorized parts distributor and service center serving Eastern Ontario, Quebec, and Atlantic Canada (New Brunswick, Prince Edward Island, and Nova Scotia).

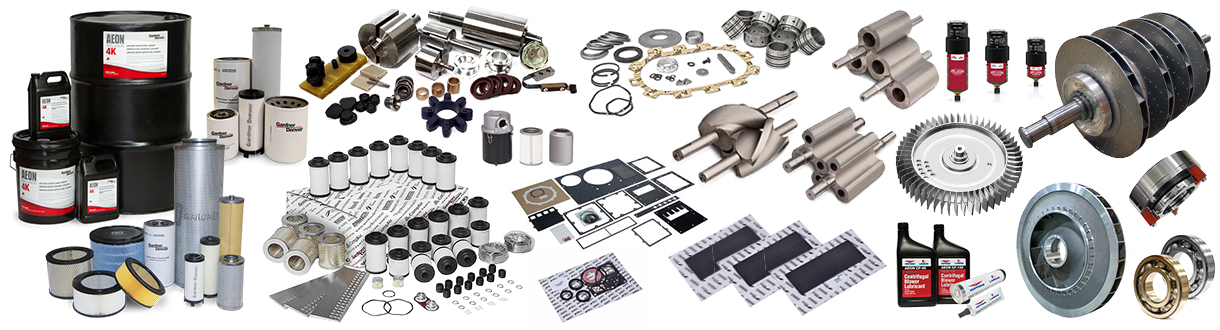

We provide original and compatible spare parts for your air and gas compressors, dryers, vacuum pumps, blowers, and other industrial equipment.

Based in Kirkland (Montreal), Quebec, we are ideally located to respond quickly to your urgent needs and ensure the reliability of your operations.

From the most common part to the most specific component, we cover not only the brands we distribute but also all compatible parts for competitor equipment.

Our extensive inventory is immediately available for essential parts of your installations, including:

Imagine the peace of mind knowing that your critical systems will be quickly restored to service thanks to our recognized expertise in industrial maintenance and the supply of guaranteed replacement components.

Avoid costly downtime and secure your production today. Get Your Personalized, Detailed Quote!

Call us directly: 514-695-4740 (local) or toll-free at 1-888-940-4740. Or complete our Quick Quote Request form for a detailed response within 24 hours.

Most commonly replaced parts by product line:

Gardner Denver compressors

- Air filter elements: Essential for protecting the compressor by removing particulates from intake air.

- Oil filter elements: Critical for maintaining lubricant cleanliness and protecting internal components.

- Air/Oil Separators: Commonly replaced to prevent oil carryover into the compressed air stream.

- Maintenance kits: Frequently used during regular maintenance, containing many small wearable components (gaskets, rings, seals, etc.).

- Compressor oil: Regularly changed to ensure performance and longevity of the compressor.

- Valve repair kits: Often required to maintain performance, especially in reciprocating compressors.

Elmo Rietschle rotary vane vacuum pumps

- Carbon vanes: Core components in rotary vane pumps; wear out with use and are replaced frequently.

- Filters elements (dry vane pumps) (Inlet/Exhaust): Protect the pump from particulates and to prevent downstream contamination

- Filter elements (oil flooded vane pumps): Regular replacement ensures efficient operation, extended pump life, and reduced wear on vanes and bearings.

- Discharge oil separators: Essential for the separation of oil from the air discharged by the pump

- Seal kits (Shaft seals, O-rings, gaskets): Essential for maintaining vacuum integrity and preventing leaks; regularly serviced.

- Bearings: Support moving parts and wear over time; often replaced during overhauls.

- Lubricants (Pump oils): Regular oil changes are critical for oil-lubricated models to ensure smooth operation and longevity.

- Rebuild kits: Frequently used for preventive maintenance; typically include vanes, seals, gaskets, and bearings.

Gardner Denver Positive Displacement Blowers (Sutorbilt, Duroflow, Heliflow, Cycloblower, Triflow)

- Air filter elements: Air filters safeguard the blower from airborne particles and are regularly replaced to maintain clean, efficient operation.

- Lubricants (AEON PD series): Changed regularly to maintain proper blower function and protect internal components.

- Overhaul kits: Frequently used in routine servicing; typically include bearings, seals, and gaskets.

- Gear kit: Includes drive gears that wear over time and are replaced to ensure synchronized rotor operation.

Elmo Rietschle Regenerative Blowers

- Motor winding: replacement is performed following a motor failure to restore functionality and prevent further electrical damage.

- Inlet filter elements: Protect the blower from airborne contaminants; replaced as part of air quality maintenance.

- Bearings: Subject to wear from constant rotation and commonly replaced to maintain performance.

- Gaskets and O-rings: Regularly replaced during maintenance or disassembly to ensure airtight sealing.

- Silencer inserts: Replacement of insulation material of inlet and outlet silencers

Hoffman & Lamson Centrifugal Blowers

- Air filter elements: They protect the blower from particulates and are replaced frequently to ensure clean operation.

- Lubricants (oil or grease): Essential for proper operation and often replaced during scheduled servicing.

- Bearing kits: Bundled components for routine maintenance, including bearings, seals, gaskets, lubricants and other wear items.

- Flexible couplings elements: Connect the blower to the drive motor and are prone to wear due to vibration and misalignment.

- Seal kits (Air & Gas): Labyrinth and carbon ring seals degrade over time, making them regular replacement items to prevent leaks and maintain efficiency.

Ro-Flo Rotary Vane Gas Compressors

- Rotor blade set: Sliding vanes are core to compression and wear with use

- Cylinder head gasket: Commonly replaced during disassembly or servicing to maintain proper sealing.

- O-rings: Essential for sealing multiple areas; often replaced during routine maintenance.

- Mechanical/Cartridge seal assembly: Critical for preventing gas leaks at the shaft; subject to wear and chemical degradation.

- Roller bearings: Support rotating components and require periodic replacement due to wear.

Gardner Denver Refrigerated Air Dryer

- Filter elements: Oil and particulate filters are standard replacements for maintaining air quality and system efficiency.

- Auto drain valves: Essential for removing condensate automatically; frequently replaced due to mechanical wear or clogging.

- Maintenance kits: Commonly used for periodic maintenance; include filters, seals, and gaskets.

- Fan motor and blade: Critical for cooling performance in air-cooled units; replaced when airflow or motor issues occur.

- Gaskets, seals, and O-rings: Often replaced during any servicing to ensure leak-proof reassembly.

- Start relay, capacitor, overload: Electrical components prone to failure with age or power surges; frequently replaced to restore compressor operation.

Belliss & Morcom Compressor

- Maintenance kits: Contain all critical wear parts and are regularly used for scheduled maintenance.

- Valves & valve kits: Suction and discharge valves wear over time due to high pressure and are frequently replaced.

- Piston & rider rings: Subject to constant friction and essential for compression efficiency, making them high-wear items.

- Piston rods and packing: Packings on compressor piston rods serve a critical function in sealing the area where the piston rod enters or exits the cylinder. Excessive wear can lead to piston rod replacement,

- Gasket kits: Required during any disassembly; frequent replacements ensure proper sealing.

- Oil system parts (especially oil seals and oil pumps): Crucial for lubrication; oil seals, in particular, are commonly replaced to prevent leaks.

- Relief valves: Safety components that may need replacement after actuation or as part of routine safety checks.

- Diaphragm unloaders repair kits: Diaphragm unloaders on Belliss & Morcom piston compressors are used as a capacity control mechanism to unload the compressor during startup and to regulate output during normal operation. Excessive wear can lead to faulty control.

Del-Monox Breathing Air Systems

- Filter elements (Cartridges): Includes coalescing prefilters, carbon afterfilters, particulate filters, and CO catalyst cartridges, all core to air purity and changed regularly.

- Catalyst cartridge (CO converter): Critical for safety; converts carbon monoxide to carbon dioxide and is replaced based on usage and time.

- Activated carbon afterfilters: Remove odors and oil vapor, often replaced as part of routine air quality maintenance.

- Particulate afterfilters: Trap fine particles and contaminants; typically replaced at scheduled intervals.

- Pressure gauges: Although not consumables, they are frequently replaced when they lose calibration or fail.

- Valves (purge exhaust, shuttle, isolation): Moving parts subject to wear from pressure cycles and environmental exposure; commonly replaced during maintenance.

- Desiccant: Although not a mechanical part, it is regularly replaced as it becomes saturated and loses its drying efficiency over time.

Gardner Denver Air Treatment System

- Air filter elements (Standard): Regularly replaced to maintain air purity and system efficiency.

- Air filter elements (Heavy duty): Used in more demanding environments; changed frequently due to higher contaminant load.

- Filter media: Custom media replacements for larger or specialized housings.

- Gaskets: Replaced during filter changes to maintain airtight seals.

- O-rings: Ensure proper sealing; commonly replaced with each filter change.

- Seals: General sealing components that are replaced during routine maintenance or when worn.

Authorized brands

Available brands